Transforming natural silk nonwovens into robust bioadhesives for in vivo tissue amendment. Journal of Cleaner Production 2021, 314, 127996.

Published in Journal of Cleaner Production, 2021

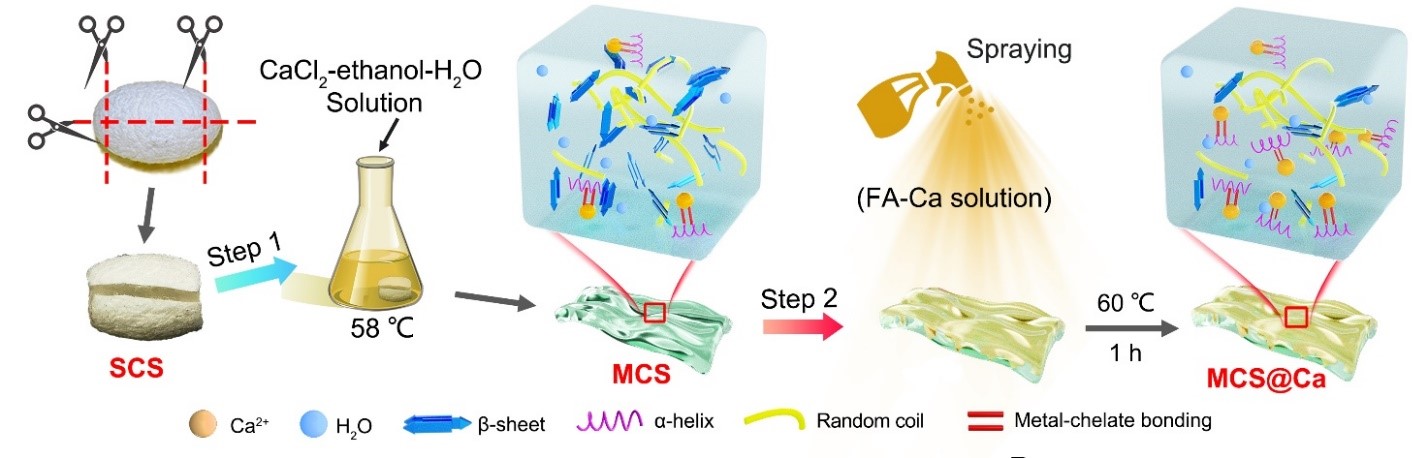

Textile manufacturing of silk generates unwindable raw silk fibers, which are treated as silk wastes for downcycling applications, thus unexpectedly demoting the luxury status of silk. As a primary trial seeking to reshape the destiny of silk wastes, the present study is focused on transforming natural silk nonwovens, as a typical model of artificial silk nonwovens, into bioadhesives for tissue repair. Herein, a technique is demonstrated for the preparation of a transparent and stretchable adhesive from a silkworm cocoon sheet (SCS), a typical natural silk nonwoven. This technique differs from the traditional method of completely dissolving silk fibers to obtain silk fibroin. Specifically, the technique entailed pretreatment of the SCS with a CaCl2-ethanol-H2O ternary solution to obtain a modified cocoon sheet (MCS), followed by surface modification with a CaCl2-formic acid (Ca-FA) solution to obtain MCS@Ca with controllable adhesion, which was achieved by adjusting the Ca2+ content in Ca-FA. The highly stretchable MCS@Ca firmly adhered to various substrates for loads as high as 54 kPa, and its performance in repairing an injured liver in vivo was superior to that of a commercial product, Sorbalgon®. Additionally, MCS@Ca effectively sealed a freshly punctured porcine heart and stomach ex vivo, thereby demonstrating its potential as a sealant. To our knowledge, this is the first trial study for on upcycling disqualified silk fibers using a convenient top-down approach to prepare robust bioadhesives for tissue repair, wherein MCS@Ca may serve to bridge the gap between advanced biomaterials and disqualified silk wastes.